Introduction

Industrial engineering is a broad field compared to other engineering disciplines. The major activities of industrial engineering stem from manufacturing industries and include work methods analysis and improvement, work measurement and the establishment of standards; machine tool analysis and design; job and workplace design; plant layout and facility design; materials handling; cost reduction; production planning and scheduling; inventory control, maintenance, and replacement; statistical quality control; scheduling; assembly-line balancing, systems, and procedures; and overall productivity improvement. Computers and information systems have necessitated additional activities and functions, including numerically controlled machine installation and programming; manufacturing systems design; computer-aided design/ computer-aided manufacturing, design of experiments, quality engineering, and statistical process control; computer simulation, operations research, and management science methods; computer applications, software development, and information technology; human factors engineering and ergonomics; systems design and integration; and robotics and automation.

Vision

The Faculty of Engineering will endeavor to nurture students for creativity and innovation dedicated to problem solving and lifelong learning for research, entrepreneurship, and professionalism.

Mission

- Develop engineers with highest level of commitment toward the betterment of the society by applying knowledge of science and engineering.

- Nurture young leaders with evolving perspectives and ethics.

- Create and disseminate knowledge and skills using modern tools.

Programs

Course Catalog

Browse here for course catalog of of BSc in Industrial & Production Engineering (IPE) offered by the Faculty of Engineering (FE)

View Course CatalogCourse Curriculum

Browse here for course curriculum of BSc in Industrial & Production Engineering (IPE) offered by the Faculty of Engineering (FE)

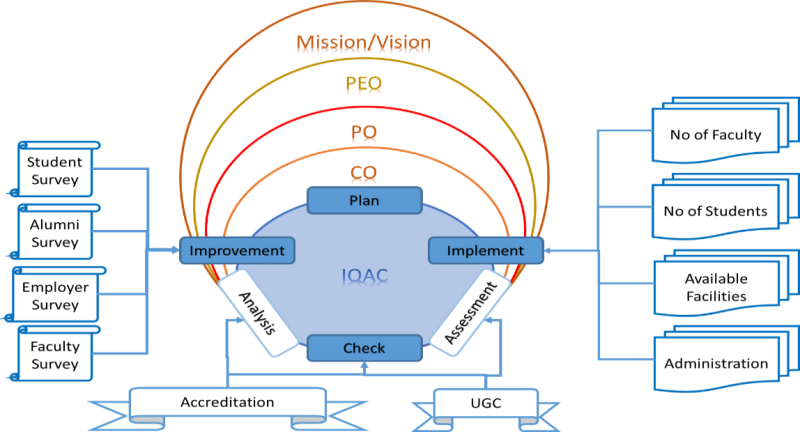

View CurriculumCurriculum Development Process

The above figure shows how the faculty of engineering is actively involved in a continuous quality improvement process of updating the program's curriculum on a regular basis. Feedback from all the relevant stakeholders like employers, industrial advisory committee, faculty members, and experts from relevant fields are analyzed and vetted to enrich the curriculum with the most up-to-date content.

Program Educational Objectives (PEOs)

Program Educational Objective (PEO) is what the program is preparing graduates for their career and professional life. Program Educational Objectives (PEOs) may be defined as “broad statements that describe what graduates are expected to attain within a few years of graduation.”

Program Educational Objectives (PEOs) are statements that describe the expected accomplishments of graduates during their first few years after graduation. The audiences for objective statements are external constituents such as prospective students, alumni, employers, transfer institutions, and student sponsors.

The Program Educational Objectives are modeled after the general objectives described by Washington Accord and BAETE, IEB. Once our students are out in the workforce, they should be able to:

|

PEO-1 |

Possess essential engineering knowledge in Production, Industrial, and other related fields that make them confident to develop a career as a professional, academic, or entrepreneur. |

|

PEO-2 |

Achieving leading roles in their organizations and communities through teamwork, professional ethics, and effective communication. |

|

PEO-3 |

Demonstrate lifelong learning through professional development, practical training, professional certification, and membership or pursuing higher studies. |

The program educational objectives were engineered within the framework of the mission of AIUB, which in turn is mapped to the mission of the Faculty of Engineering (FE) and the mission of the Department of Industrial and Production Engineering (IPE) is the outcome. Below is a representation of association of the mission statements of the Department. of IPE with the PEOs of the program.

| Mission/Vision Statements | Program Educational Objectives (PEOs) | |||

|

PEO-1: Possess essential engineering knowledge in Industrial, Production and other related fields that make them confident to develop career as professional, academic or entrepreneur. |

PEO-2: Achieving leading roles in their organizations and communities through teamwork, professional ethics and effective communication. |

PEO-3: Demonstrate lifelong learning through professional development, practical training, professional certification and membership or pursuing higher studies. |

||

| University Mission | ||||

|

Provide quality and excellent computer-based academic programs responsive to the emerging challenges of the time. |

H | H | H | |

|

Nurture and produce competent world class professional. |

H | H | H | |

| University Vision | ||||

|

Envisions promoting professionals and excellent leadership catering to the technological progress and development needs of the country. |

H | H | H | |

| Department Mission | ||||

|

Educate young leaders for academia, industry, entrepreneurship and public and private organization |

H | M | H | |

|

Create knowledge through innovative research and collaboration. |

M | H | H | |

|

Serve the communities at national, regional and global levels. |

M | M | H | |

| Department Vision | ||||

|

To become a front runner. |

H | H | H | |

|

Contribute value for the knowledge-based economy and welfare. |

H | M | H | |

|

(H: High, M: Medium, L: Low) |

||||

The process of achievement of PEO is divided into equal contributions, stated from responses given by key stakeholders like Employers and Alumni. Employers happen to supervise our graduates and know the performance of their traits in four key areas of graduate attributes, knowledge, work skills, communication skills, and interpersonal skills, while our graduates provide feedback regarding the hardship, they have faced with the lacking in any of the attributes associated with our curriculum.

Each of the key graduate attributes is further subdivided into subcategories (as shown in the list below) to provide an in-depth understanding of our graduates’ status in that specific field.

| PEO-1 | Job knowledge (knowledge on subject matter) |

| IT Knowledge | |

| Knowledge in designing a system component or process | |

| Technical knowledge | |

| Ability to work in teams | |

| Leadership | |

| Independent thinking/ Self Confidence | |

| Self-Motivation/ Commitment to job | |

| Reliability | |

| Appreciation of ethical values | |

| Adaptability | |

| PEO-2 | Oral communication |

| Report writing | |

| Presentation skills | |

| Competency in English language | |

| Time management skills | |

| Judgment | |

| Problem formulation, solving and decision-making skills | |

| Collecting and analyzing appropriate data | |

| Ability to link theory to Practice | |

| Discipline | |

| Sense of Responsibility | |

| Ethical and moral value | |

| PEO-3 | Aptitude in attending professional seminars, trainings or workshops |

| Aptitude with regards to having professional degrees | |

| Having various professional affiliations |

Program & Course Outcomes

The Department of IPE follows the Board of Accreditation for Engineering and Technical Education (BAETE) under the Institution of Engineers Bangladesh (IEB) for local accreditation and development of Outcome-Based Education (OBE) and its implementation in the B.Sc. in IPE program, using the standards and regulations mentioned in the BAETE manual.

The program's PEOs have been derived from the department's mission and vision, as shown in the figure below.

The knowledge profile should have eight attributes (K1 to K8), indicating the volume of learning and attributes against which graduates must be able to perform.

|

K1: A systematic, theory-based understanding of the natural sciences applicable to the discipline |

|

K2: Conceptually-based mathematics, numerical analysis, statistics and formal aspects of computer and information science to support analysis and modelling applicable to the discipline |

|

K3: A systematic, theory-based formulation of engineering fundamentals required in the engineering discipline |

|

K4: Engineering specialist knowledge that provides theoretical frameworks and bodies of knowledge for the accepted practice areas in the engineering discipline; much is at the forefront of the discipline. |

|

K5: Knowledge that supports engineering design in a practice area |

|

K6: Knowledge of engineering practice (technology) in the practice areas in the engineering discipline |

|

K7:Comprehension of the role of engineering in society and identified issues in engineering practice in the discipline: ethics and the professional responsibility of an engineer to public safety; the impacts of engineering activity: economic, social, cultural, environmental and sustainability |

|

K8: Engagement with selected knowledge in the research literature of the discipline |

A program that builds this type of knowledge and develops the attributes listed above is typically achieved in 4 to 5 years of study, depending on the level of students at entry.

Twelve Program Outcomes (POs) have been outlined in accordance with the mission and vision statements of the department of IPE. These are statements that describe what students are expected to know and be able to do by the time of graduation. These relate to the skills, knowledge, and behaviors that students acquire in their matriculation through the program. The broader definition of the program outcomes (POs) has been listed below.

|

No. |

Program Outcomes (POs) |

|

a |

Engineering knowledge: Apply knowledge of mathematics, natural science, engineering fundamentals and an engineering specialization as specified in K1 to K4 respectively to the solution of complex engineering problems. |

|

b |

Problem analysis: Problem analysis: Identify, formulate, research literature and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences and engineering sciences. (K1 to K4) |

|

c |

Design/development of solutions: Design solutions for complex engineering problems and design systems, components or processes that meet specified needs with appropriate consideration for public health and safety, cultural, societal, and environmental considerations. (K5) |

|

d |

Investigation: Conduct investigations of complex problems using research-based knowledge (K8) and research methods including design of experiments, analysis and interpretation of data, and synthesis of information to provide valid conclusions. |

|

e |

Modern tool usage: Create, select and apply appropriate techniques, resources, and modern engineering and IT tools, including prediction and modelling, to complex engineering problems, with an understanding of the limitations. (K6) |

|

f |

The engineer and society: Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to professional engineering practice and solutions to complex engineering problems. (K7) |

|

g |

Environment and sustainability: Understand and evaluate the sustainability and impact of professional engineering work in the solution of complex engineering problems in societal and environmental contexts. (K7) |

|

h |

Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of engineering practice. (K7) |

|

i |

Individual work and teamwork: Function effectively as an individual, and as a member or leader in diverse teams and in multi-disciplinary settings. |

|

J |

Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions. |

|

k |

Project management and finance: Demonstrate knowledge and understanding of engineering management principles and economic decision-making and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments. |

|

l |

Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. |

Engineering problems that involve wide-ranging or conflicting technical, engineering, and other issues, have no obvious solution, and require abstract thinking and originality in analysis to formulate suitable models are defined as complex engineering problems. The abilities to solve complex problems in engineering are essential in the curriculum of engineering education. The list of complex engineering problems (P1 to P7) clarifies the definition of Complex Engineering Problem by establishing seven range, or characteristics, of problem-solving.

| Attribute | Complex Engineering Problems have characteristic WP1 and some or all of WP2 to WP7: | Related POs |

|

Depth of Knowledge Required |

P1: Cannot be resolved without in-depth engineering knowledge at the level of one or more of WK3, WK4, WK5, WK6 or WK8 which allows a fundamentals-based, first principles analytical approach |

PO-a, PO-b, PO-c, PO-d, PO-e, PO-f, PO-g |

|

Range of conflicting requirements |

P2: Involve wide-ranging or conflicting technical, engineering, and other issues |

PO-a, PO-b, PO-d, PO-e, PO-g |

|

Depth of analysis required |

P3: Have no obvious solution and require abstract thinking, originality in analysis to formulate suitable models |

PO-a, PO-c, PO-e, PO-f |

|

Familiarity of issues |

P4: Involve infrequently encountered issues |

PO-b, PO-d, PO-e |

|

Extent of applicable codes |

P5: Are outside problems encompassed by standards and codes of practice for professional engineering |

PO-b, PO-d, PO-e |

|

Extent of stakeholder involvement and conflicting requirements |

P6: Involve diverse groups of stakeholders with widely varying needs |

PO-a, PO-b, PO-d, PO-e, PO-g |

|

Interdependence |

P7: Are high-level problems including many component parts or sub-problems |

PO-a, PO-c, PO-e, PO-f |

| In addition, in the context of the Professional Competencies | ||

|

Consequences |

EP1: Have significant consequences in a range of contexts |

|

|

Judgement |

EP2: Require judgement in decision making |

|

There are five attributes of activities students can be involved in when solving Complex Engineering Problem. A Complex Engineering Activity or Project is that which has some or all of the following attributes:

| Attribute | Complex Activities | Related POs |

|

Range of resources |

A1: Involve the use of diverse resources (and for this purpose resources includes people, money, equipment, materials, information and technologies) |

PO-j |

|

Level of interactions |

A2: Require resolution of significant problems arising from interactions between wide ranging or conflicting technical, engineering or other issues, |

PO-j |

|

Innovation |

A3: Involve creative use of engineering principles and research-based knowledge in novel ways. |

PO-j |

|

Consequences to society and the environment |

A4: Have significant consequences in a range of contexts, characterized by difficulty of prediction and mitigation |

PO-j |

|

Familiarity |

A5: Can extend beyond previous experiences by applying principles-based approaches |

PO-j |

The relationship between Program Outcomes (POs) and PEOs has been illustrated below:

|

Program Outcomes (POs) |

PEO-1 (Knowledge and Skills) |

PEO-2 (Interpersonal Skills) |

PEO-3 (Continual Professional Development) |

|

|

PO a |

Engineering Knowledge: |

X | ||

|

PO b |

Problem Analysis: |

X | ||

|

PO c |

Design/ development of solutions: |

X |

|

X |

|

PO d |

Investigation |

X | X |

|

|

PO e |

Modern Tool Usage: |

X | X | X |

|

PO f |

The Engineer and Society |

|

X | X |

|

PO g |

Environment and Sustainability: |

X | X | |

|

PO h |

Ethics: |

X |

|

|

|

PO i |

Individual and Team work: |

X | X | X |

|

PO j |

Communication: |

X | X | X |

|

PO k |

Project Management and Finance: |

X |

|

X |

|

PO l |

Lifelong learning: |

X | X | X |

In order to access the 12 POs through COs, these POs has been subdivided, which are given with special code as Program Outcome Indicator (POI), and been mapped with Knowledge Profile (KP), Complex Problem (CP) and Complex Activity (CA). The POI to PO mapping has been shown in the following table.

| POs | POI Code | POI Statement |

|

a. Engineering Knowledge |

P.a.1.C3 |

Apply information and concepts in natural science with the familiarity of issues. (K1) |

|

P. a.2.C3 |

Apply information and concepts of mathematics to solve complex engineering problems with a range of conflicting requirements. (K2, P1, P2, and P6) |

|

|

P.a.3.C3 |

Apply information and concepts in engineering fundamentals with the familiarity of issues. (K3) |

|

|

P.a.4.C3 |

Apply information and concepts in specialized engineering sciences with the in-depth of analysis of a complex engineering problem. (K4, P1, P3, and P7) |

|

|

b. Problem Analysis |

P.b.1.C4 |

Identify and relate first principles of mathematics, natural sciences and engineering sciences to solve complex engineering problems. (K1, K2, K3, P1, P2 and P6) |

|

P.b.2.C4 |

Formulate solutions, procedures, and methods to solve complex engineering problems. (P1, P4 and P5). |

|

|

P.b.3.C4 |

Analyze and solves complex engineering problems reaching substantiated conclusion. (K4, P1, P2 and P6) |

|

|

P.b.4.C5 |

Research literature and Critically evaluates the validity and accuracy of existing solution methods using specialized engineering knowledge. (K4) |

|

|

c. Design/ development of solutions |

P.c.1.C2 |

Identify the different components or processes of complex engineering problems. (P1, P3 and P7) |

|

P.c.2.C3 |

Develop solution for different components of complex engineering problem. (P1, P3 and P7) |

|

|

P.c.3.C4 |

Develop probable solutions that meet specified needs with appropriate consideration for public health and safety, culture, societal and environmental considerations. (K5) |

|

|

d. Investigation |

P.d.1.P3 |

Design Experiment to test complex engineering problem for certain constrains through appropriate research. (K8, P1, P2 and P6) |

|

P.d.2.C4 |

Analysis and Interpretation of collected data to provide valid conclusion acknowledging the limitations. |

|

|

P.d.3.C6 |

Develop and Synthesis of complex engineering problems using substantial engineering knowledge. (P1, P4 and P5) |

|

|

e. Modern Tool Usage |

P.e.1.C3 |

Select and Apply appropriate techniques to solve complex engineering problems using modern engineering tools considering the limitations. (P1, P2 and P6) |

|

P.e.2.P4 |

Use engineering tools for prediction and modeling of complex engineering problems considering the practice in Electrical and Electronic Engineering discipline. (P1, P4 and P5) |

|

|

P.e.3.P5 |

Create relevant resources for complex engineering problems using modern engineering tools. (K6, P1, P3 and P7) |

|

|

f. The Engineer and Society |

P.f.1.A3 |

Accepts and Recognize the role of engineering in society, health, safety, legal and culture. |

|

P.f.2.C5 |

Design solution for complex engineering problem in accordance with professional practices. (K7, P1, P3 and P7) |

|

|

g. Environment and Sustainability |

P.g.1.C5 |

Evaluate sustainability of complex engineering problems considering society and environment. (K7, P1, P2 and P6) |

|

P.g.2.C5 |

Identify impact on society and environment for professional engineering solutions. (K7) |

|

|

h. Ethics |

P.h.1.A5 |

Demonstrates knowledge of ethical standards (i.e. Code of Ethics) |

|

P.h.2.A4 |

Demonstrates individual responsibilities based on norms of engineering practice. (K7) |

|

|

i. Individual and Teamwork |

P.i.1.A2 |

Function as effective team leader/member in multi-disciplinary problems. |

|

P.i.2.A2 |

Displays good interpersonal skills as a member/leader. |

|

|

P.i.3.A5 |

Demonstrate individual skills in solving multi-disciplinary problems. |

|

|

j. Communication |

P.j.1.A2 |

Demonstrates an ability to effectively give and respond to clear instructions. (A1 andA3) |

|

P.j.2.P3 |

Produces written engineering reports by applying principle based approaches and design documentation on complex engineering activities for different stake holders. (A1 andA5) |

|

|

P.j.3.A2 |

Perform effective oral presentation on complex engineering activities. (A2 andA4) |

|

|

k. Project Management and Finance |

P.k.1.P4 |

Apply engineering management principles and economic decision making to solve engineering projects as a team. |

|

P.k.2.P4 |

Manage multi-disciplinary projects as a member/leader. |

|

|

P.k.3.A5 |

Demonstrate competency in completing individual engineering project based on relevant management principles and economic models. |

|

|

l. Lifelong learning |

P.l.1.A1 |

Investigate and gather information on a given engineering issue. |

|

P.l.2.A4 |

Seek and use resources in solving engineering problems. |

|

|

P.l.3.A5 |

Recognizing the need for continuing education and participation in professional societies and meetings. |

Mapping of Knowledge Profile, Complex Engineering Problems and Complex Engineering Activities with Courses

| ID | Knowledge Profile (KP) | COs (POI) | Courses |

|

K1 |

A systematic, theory-based understanding of the natural sciences applicable to the discipline |

P.a.1.C3 |

SIMULATION AND DESIGN IN IE |

|

SIMULATION AND DESIGN IN IE LAB |

|||

|

P.b.1.C4 |

MANUFACTURING AND PRODUCTION RESOURCE PLANNING |

||

|

CAPSTONE PROJECT [IPE] |

|||

|

K2 |

Conceptually based mathematics, numerical analysis, statistics and the formal aspects of computer and information science to support analysis and modeling applicable to the discipline |

P.a.2.C3 |

TECH MAJOR 4 |

|

STATISTICAL DECISION MAKING FOR ENGINEERS |

|||

|

P.b.1.C4 |

INDUSTRIAL & OPERATIONS MANAGEMENT |

||

|

MACHINE TOOLS |

|||

|

K3 |

A systematic, theory-based formulation of engineering fundamentals required in the engineering discipline |

P.a.3.C3 |

COMPUTER APPLICATION IN IE |

|

COMPUTER APPLICATION IN IE LAB |

|||

|

P.b.1.C4 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

K4 |

Engineering specialist knowledge that provides theoretical frameworks and bodies of knowledge for the accepted practice areas in the engineering discipline; much is at the forefront of the discipline |

P.a.4.C3 |

MANUFACTURING AND PRODUCTION PROCESS, I |

|

MANUFACTURING AND PRODUCTION PROCESS, I LAB |

|||

|

P.b.3.C4 |

MEASUREMENT AND QUALITY CONTROL |

||

|

INDUSTRIAL TRAINING / SEMINAR / WORKSHOPS |

|||

|

P.b.4.C5 |

TECH MAJOR 3 |

||

|

CAPSTONE PROJECT [IPE] |

|||

|

K5 |

Knowledge that supports engineering design in a practice area |

P.c.3.C4 |

MACHINE JOB SHOP- I (DRILLING, WELDING, MILLING AND TURNING) |

|

MACHINE JOB SHOP- II (SHEET METAL FORMING AND CASTING) |

|||

|

K6 |

Knowledge of engineering practice (technology) in the practice areas in the engineering discipline |

P.e.3.P5 |

STATISTICAL DECISION MAKING FOR ENGINEERS |

|

INDUSTRIAL & OPERATIONS MANAGEMENT |

|||

|

K7 |

Comprehension of the role of engineering in society and identified issues in engineering practice in the discipline: ethics and the engineer’s professional responsibility to public safety; the impacts of engineering activity; economic, social, cultural, environmental and sustainability |

P.f.2.C5 |

MACHINE TOOLS |

|

MACHINE TOOLS LAB |

|||

|

P.g.1.C5 |

INDUSTRIAL, ERGONOMICS AND PRODUCTION SAFETY |

||

|

MANUFACTURING AND PRODUCTION PROCESS II |

|||

|

P.g.2.C5 |

MANUFACTURING AND PRODUCTION PROCESS II LAB |

||

|

SIMULATION AND DESIGN IN IE |

|||

|

P.h.2.A4 |

SIMULATION AND DESIGN IN IE LAB |

||

|

MANUFACTURING AND PRODUCTION RESOURCE PLANNING |

|||

|

K8 |

Engagement with selected knowledge in the research literature of the discipline |

P.d.1.P3 |

INTERNSHIP |

|

TECH MAJOR 4 |

| Complex Engineering Problem (CP) | COs (POI) | Courses | |

|

P1 |

Depth of knowledge: Cannot be resolved without in-depth engineering knowledge at the level of one or more of KP3, KP4, KP5, KP6 or KP8 which allows a fundamentals-based, first principles analytical approach |

P.a.2.C3 |

PRODUCTION & INVENTORY CONTROL |

|

WORK DESIGN |

|||

|

P.a.4.C3 |

ENGINEERING MATERIALS & PROCESSES LAB |

||

|

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

|||

|

P.b.1.C4 |

PRODUCTION & INVENTORY CONTROL |

||

|

WORK DESIGN |

|||

|

P.b.2.C4 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

P.b.3.C4 |

STATISTICAL DECISION MAKING FOR ENGINEERS |

||

|

INDUSTRIAL & OPERATIONS MANAGEMENT |

|||

|

P.c.1.C2 |

MACHINE TOOLS |

||

|

MACHINE TOOLS LAB |

|||

|

P.c.2.C3 |

COMPUTER APPLICATION IN IE |

||

|

COMPUTER APPLICATION IN IE LAB |

|||

|

P.d.1.P3 |

STATISTICAL DECISION MAKING FOR ENGINEERS |

||

|

INDUSTRIAL & OPERATIONS MANAGEMENT |

|||

|

P.d.3.C6 |

MACHINE TOOLS |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS |

|||

|

P.e.1.C3 |

PRODUCTION & INVENTORY CONTROL |

||

|

WORK DESIGN |

|||

|

P.e.2.P4 |

CAPSTONE PROJECT [IPE] |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS LAB |

|||

|

P.e.3.P5 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

P.f.2.C5 |

CAPSTONE PROJECT [IPE] |

||

|

MACHINE JOB SHOP- II (SHEET METAL FORMING AND CASTING) |

|||

|

P.f.1.C5 |

MACHINE JOB SHOP- I (DRILLING, WELDING, MILLING AND TURNING) |

||

|

INTRODUCTION TO INDUSTRIAL ENGINEERING |

|||

|

P2 |

Range of conflicting requirements: Involve wide-ranging or conflicting technical, engineering and other issues |

P.a.2.C3 |

ENGINEERING MATERIALS & PROCESSES |

|

ENGINEERING MATERIALS & PROCESSES LAB |

|||

|

P.b.1.C4 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

P.b.3.C4 |

WORK DESIGN |

||

|

TECH MAJOR 1 |

|||

|

P.d.1.P3 |

CAPSTONE PROJECT [IPE] |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

P.e.1.C3 |

MANUFACTURING AND PRODUCTION PROCESS, I |

||

|

MANUFACTURING AND PRODUCTION PROCESS, I LAB |

|||

|

P.g.1.C5 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

INTRODUCTION TO INDUSTRIAL ENGINEERING |

|||

|

P3 |

Depth of analysis: Have no obvious solution and require abstract thinking, originality in analysis to formulate suitable models |

P.a.4.C3 |

INDUSTRIAL, ERGONOMICS AND PRODUCTION SAFETY |

|

MANUFACTURING AND PRODUCTION PROCESS II |

|||

|

P.c.1.C2 |

MANUFACTURING AND PRODUCTION PROCESS II LAB |

||

|

COMPUTER INTEGRATED MANUFACTURING |

|||

|

P.c.2.C3 |

COMPUTER INTEGRATED MANUFACTURING LAB |

||

|

TECH MAJOR 2 |

|||

|

P.e.3.P5 |

MEASUREMENT AND QUALITY CONTROL |

||

|

INDUSTRIAL TRAINING / SEMINAR / WORKSHOPS |

|||

|

P.f.2.C5 |

TECH MAJOR 3 |

||

|

CAPSTONE PROJECT [IPE] |

|||

|

P4 |

Familiarity of issues: Involve infrequently encountered issues |

P.b.2.C4 |

ENGINEERING MATERIALS & PROCESSES LAB |

|

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

|||

|

P.d.3.C6 |

PRODUCTION & INVENTORY CONTROL |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS |

|||

|

P.e.2.P4 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS LAB |

|||

|

P5 |

Extent of applicable codes: Are outside problems encompassed by standards and codes of practice for professional engineering |

P.b.2.C4 |

CAPSTONE PROJECT [IPE] |

|

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

|||

|

P.d.3.C6 |

WORK DESIGN |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS |

|||

|

P.e.2.P4 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

COMPUTER AIDED DESIGN IN MANUFACTURING AND PRODUCTION PROCESS LAB |

|||

|

P6 |

Extent of stakeholder involvement and conflicting requirements: Involve diverse groups of stakeholders with widely varying needs |

P.a.2.C3 |

ENGINEERING MATERIALS & PROCESSES LAB |

|

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

|||

|

P.b.1.C4 |

PRODUCTION & INVENTORY CONTROL |

||

|

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

|||

|

P.b.3.C4 |

CAPSTONE PROJECT [IPE] |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

|

P.d.1.P3 |

SIMULATION AND DESIGN IN IE |

||

|

SIMULATION AND DESIGN IN IE LAB |

|||

|

P.e.1.C3 |

MANUFACTURING AND PRODUCTION RESOURCE PLANNING |

||

|

CAPSTONE PROJECT [IPE] |

|||

|

P.g.1.C5 |

TECH MAJOR 4 |

||

|

INTRODUCTION TO INDUSTRIAL ENGINEERING |

|||

|

P7 |

Interdependence: Are high level problems including many component parts or sub-problems |

P.a.4.C3 |

SIMULATION AND DESIGN IN IE |

|

SIMULATION AND DESIGN IN IE LAB |

|||

|

P.c.1.C2 |

MANUFACTURING AND PRODUCTION RESOURCE PLANNING |

||

|

INTERNSHIP |

|||

|

P.c.2.C3 |

TECH MAJOR 4 |

||

|

INTRODUCTION TO INDUSTRIAL ENGINEERING |

|||

|

P.e.3.P5 |

CAPSTONE PROJECT [IPE] |

||

|

ENGINEERING MATERIALS & PROCESSES LAB |

|||

|

P.f.2.C5 |

PROJECT & ENVIRONMENTAL MANAGEMENT AND ORGANIZATION |

||

|

PRODUCTION & INVENTORY CONTROL |

|||

| Complex Engineering Activities (CA) | COs (POI) | Courses | |

|

A1 |

Range of resources: Involve the use of diverse resources (and for this purpose resources include people, money, equipment, materials, information and technologies) |

P.j.1.A2 |

Capstone Project |

|

Machines Shop 1 Lab |

|||

|

P.j.2.P3 |

Capstone Project |

||

|

Engineering Ethics and Environmental Protection |

|||

|

A2 |

Level of interaction: Require resolution of significant problems arising from interactions between wide-ranging or conflicting technical, engineering or other issues |

P.j.3.A2 |

Capstone Project |

|

Machines Shop 2 Lab |

|||

|

A3 |

Innovation: Involve creative use of engineering principles and research-based knowledge in novel ways |

P.j.1.CA2 |

Capstone Project |

|

Machines Shop 1 Lab |

|||

|

A4 |

Consequences for society and the environment: Have significant consequences in a range of contexts, characterized by difficulty of prediction and mitigation |

P.j.3.A2 |

Capstone Project |

|

Machines Shop 2 Lab |

|||

|

A5 |

Familiarity: Can extend beyond previous experiences by applying principles-based approaches |

P.j.2.P3 |

Capstone Project |

|

Engineering Ethics and Environmental Protection |